-

Sexual Wellness

Sexual WellnessSex Toys and Pregnancy: Safety and Pleasure

Are sex toys safe to use during pregnancy? TL; DR: yes! Sex toys are generally safe to use during pregnancy in the absence of complications.

-

Sexual Wellness

Sexual WellnessVoyeurism: Balancing Privacy and Consent

Voyeurism can be thrilling and there are ways to explore it consensually without violating someone’s privacy.

-

Sexual Wellness

Sexual WellnessDIY Sex Toys: Safety and Creativity

Making sex toys is the most pleasurable form of crafting, but there are a few considerations to keep in mind.

-

Sexual Wellness

Sexual WellnessA Guide to Safe and Pleasurable Casual Sex

Engaging in casual sex can be a fun and pleasurable experience when approached with communication, consent, and responsibility in mind.

-

Sexual Wellness

Sexual WellnessMyths About the Male Orgasm

While it may seem straightforward, delving into the intricacies of the male orgasm reveals a fascinating interplay of physical, emotional, and psychological factors.

-

Sexual Wellness

Sexual WellnessMy Dog is Ruining My Sex Life

Your cart (0)

Free shipping on orders over $100!

Cart Drawer Recommendations

-

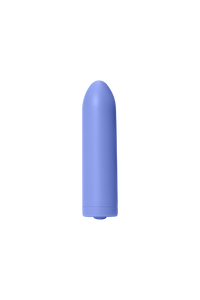

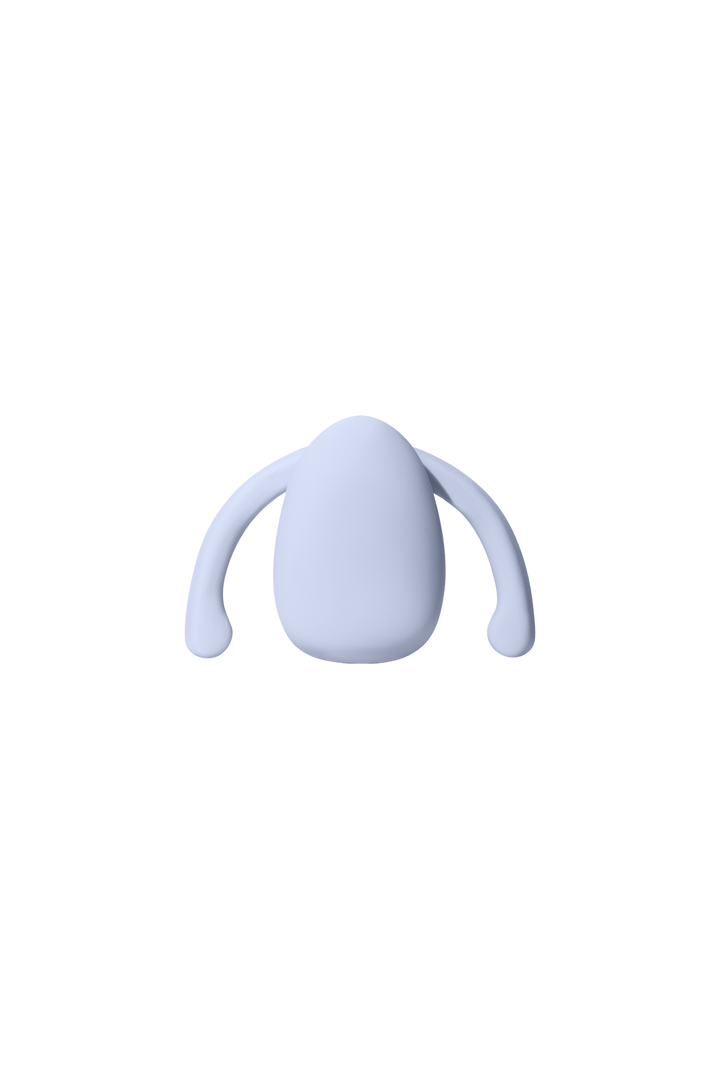

Zee$30.00

Zee$30.00 -

Arousal Serum$30.00

Arousal Serum$30.00 -

O-Face Hat$15.00

O-Face Hat$15.00 -

Dame Socks$8.00

Dame Socks$8.00 -

Body Wipes$10.00

Body Wipes$10.00 -

Dip$35.00

Dip$35.00 -

O-Face Bucket Hat$20.00

O-Face Bucket Hat$20.00 -

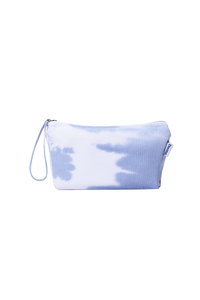

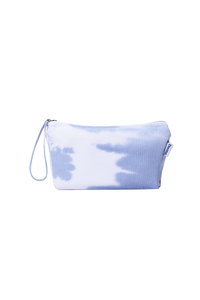

Stash$25.00

Stash$25.00 -

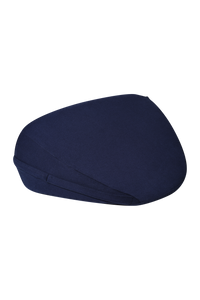

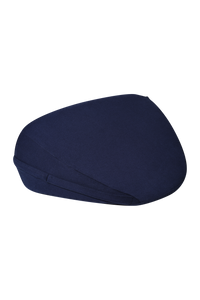

Pillo$95.00

Pillo$95.00 -

Pillo Outer Cover$15.00

Pillo Outer Cover$15.00 -

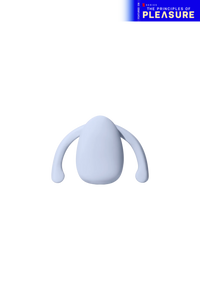

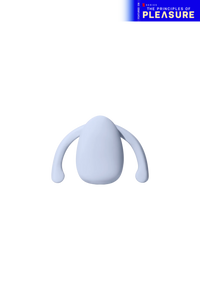

Eva$140.00

Eva$140.00 -

Pom$99.00

Pom$99.00 -

Grip$9.00

Grip$9.00 -

Gift Card$25.00

Gift Card$25.00 -

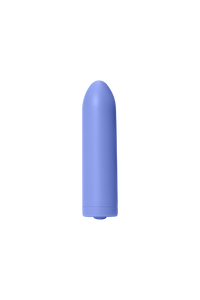

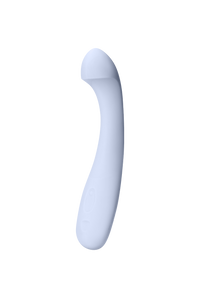

Arc$79.20

Arc$79.20 -

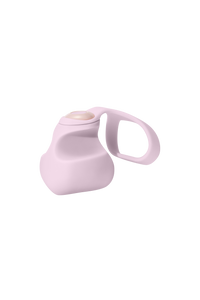

Aer$119.00

Aer$119.00 -

Spare Charging Cable$4.00

Spare Charging Cable$4.00 -

Com$119.00

Com$119.00 -

Eva Charging Base$25.00

Eva Charging Base$25.00 -

Massage Oil$24.00

Massage Oil$24.00 -

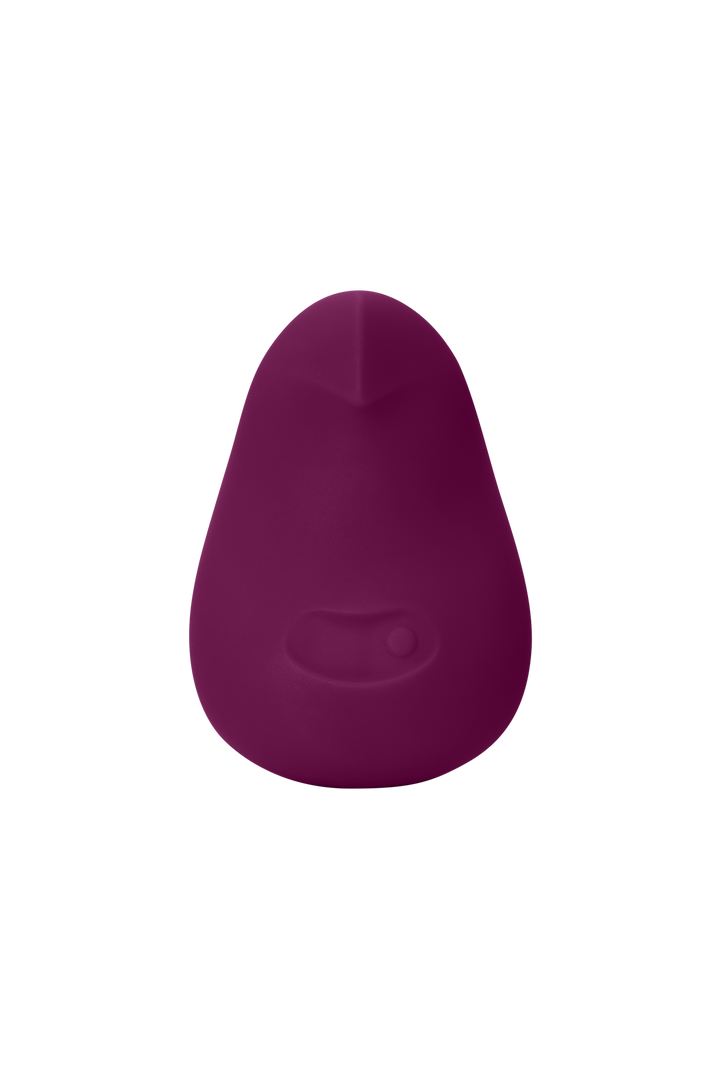

Fin$65.00

Fin$65.00 -

Body Wipe Sachets$12.00

Body Wipe Sachets$12.00

Have an account?

Log in to check out faster.